Specifically, Error 501, often alongside Error 500, points to a problem with the printer’s ability to detect or properly handle the transfer film.

Common Causes of Error 501:

Transfer Film Misalignment/Improper Loading:

The most frequent cause. The retransfer film might not be loaded correctly onto its spool. It could be off-center, wrinkled, or not threaded properly through the printer’s path.

- The green spool (or similar component) holding the film might have taken a knock in transit or during loading, causing the film to be misaligned.

Film Sensor Issues:

- The HDP6600 relies on sensors to detect the presence and correct positioning of the transfer film.

- These sensors might be dirty, obstructed, damaged, or simply need recalibration. Dirt on the purple film roller can also contribute to “Check Film” errors.

Damaged or Defective Transfer Film:

- The retransfer film itself might be damaged, torn, creased, or otherwise defective. This can happen during manufacturing, shipping, or mishandling.

- An internal defect in the film roll can prevent it from feeding smoothly or being properly detected.

Incorrect Film Type:

- While less common for Error 501 specifically, using an incompatible or non-genuine transfer film can sometimes trigger sensor errors, as the printer may not correctly identify the film’s properties.

Firmware/Driver Issues (Less common but possible):

- Outdated printer firmware or driver issues can sometimes lead to communication problems that manifest as sensor errors.

Troubleshooting Steps for Error 501:

Before contacting support, try these common troubleshooting steps:

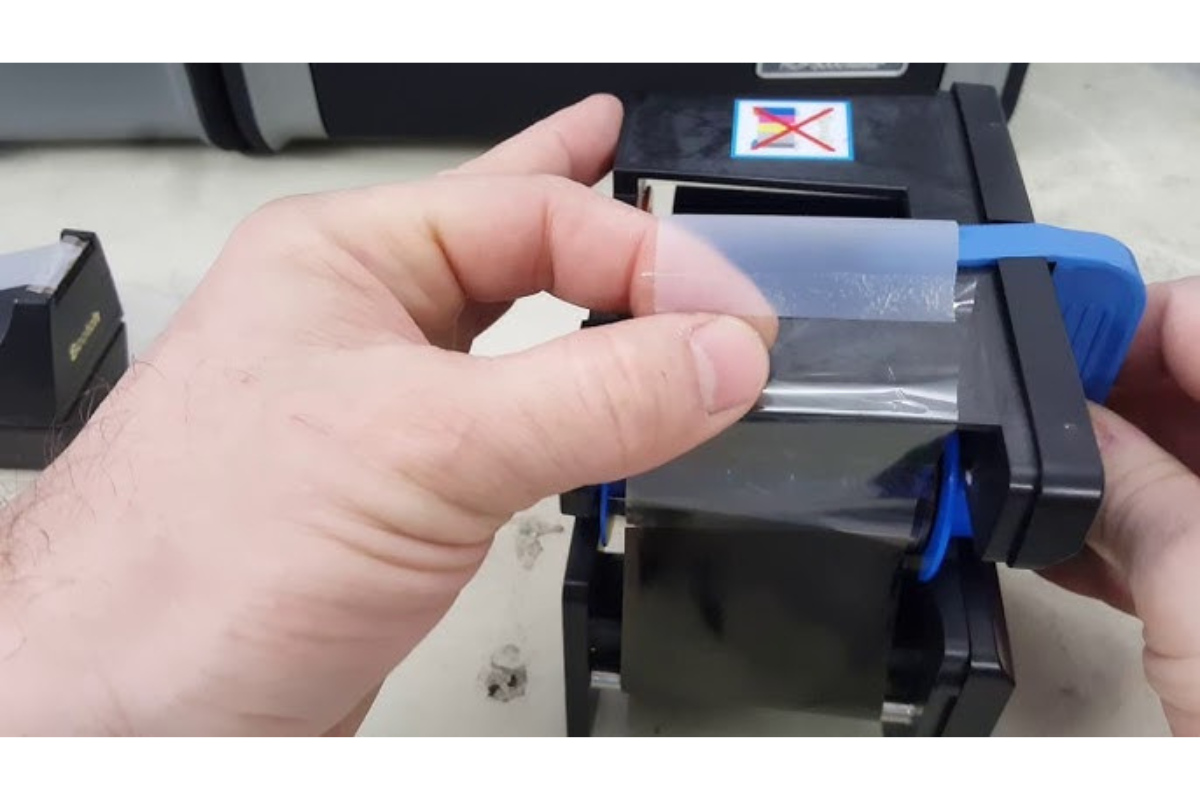

Inspect and Reload the Transfer Film:

- Open the printer cover and carefully examine the transfer film spool.

- Ensure the film is perfectly centered and aligned on the spool and that there are no wrinkles, tears, or damage.

- Remove the film cartridge completely and then reload it carefully and correctly according to your HDP6600 user manual. Make sure it clicks securely into place.

Check for Physical Damage to the Film:

- Look closely at the film itself for any signs of physical damage. If it’s torn, creased, or shows other defects, replace it with a new, genuine Fargo HDP6600 retransfer film (e.g., FARGO 084053 HDP Film).

Clean the Sensors:

- Gently clean the sensors associated with the transfer film path using a soft, dry, lint-free cloth or a cleaning card. Refer to your printer’s user manual to locate these specific sensors. A dirty purple film roller can often cause these errors.

Calibrate Film Sensors:

- The HDP6600 allows for sensor calibration, often recommended with every new roll of film. You can typically do this through the printer’s driver settings on your computer (e.g., in “Printing Preferences” > “Utilities” > “Calibrate Sensors”).

Power Cycle the Printer:

- Turn the printer off, unplug it from the power source, wait for a few moments (e.g., 30 seconds), then plug it back in and turn it on. This can sometimes clear temporary glitches.

Update Firmware and Driver:

- Ensure that your HDP6600 printer has the latest firmware and that you are using the most up-to-date printer driver on your computer. Visit the HID Global website’s support section for the HDP6600 to download the latest versions.

Please contact authorized HID FARGO distributors like Ahmed Infotech Solutions (+92-309-786-2487) or AITS Distributions for technical assistance and service.